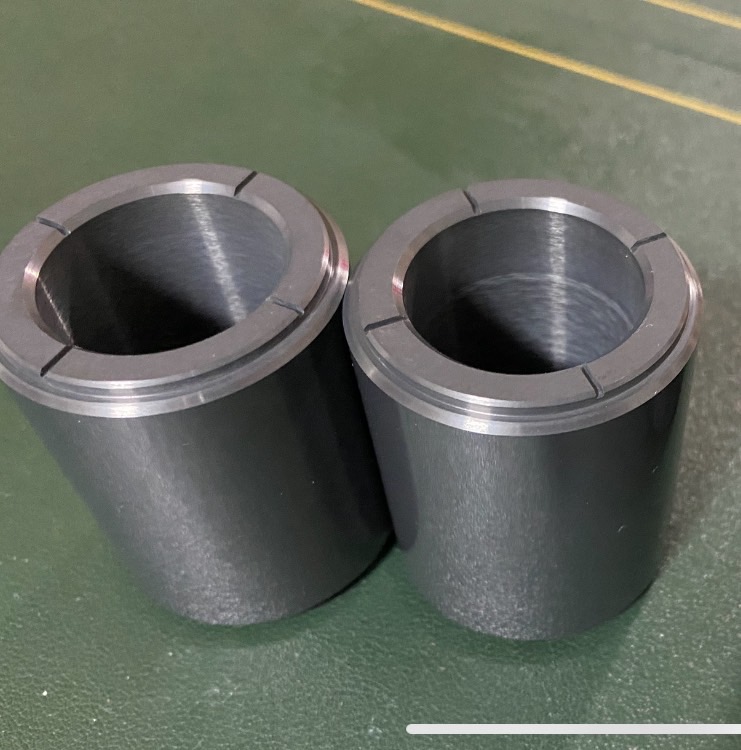

ustom Silicon Carbide (SiC) Pump Components

- Application Fields:

- 1. Wear-resistant pump components

- 2. Ceramic bearings and heat exchangers

- 3. Chemical pump parts and various nozzles

- 4. High-temperature cutting tools and refractory plates

- 5. Mechanical wear-resistant parts

- 6. Steelmaking reducers, surge arresters

- 7. Other semiconductor processing components

- Machining Method:

- 1. Diamond grinding and cutting

Silicon Carbide (SiC)

Silicon carbide is a wide-bandgap ceramic material featuring high breakdown voltage, strong electric field resistance, and high current density. In addition to excellent thermal conductivity, it also exhibits superior hardness, heat resistance, oxidation resistance, and corrosion resistance compared to traditional ceramics.

These properties make SiC widely adopted in structural components for mechanical engineering and sealing parts for chemical applications, including extreme conditions such as strong acids, strong alkalis, high abrasion, high temperatures, and aerospace environments.

Main Features:

● Excellent wear resistance

● Outstanding corrosion resistance

● Superior oxidation resistance

● High thermal conductivity and heat dissipation efficiency

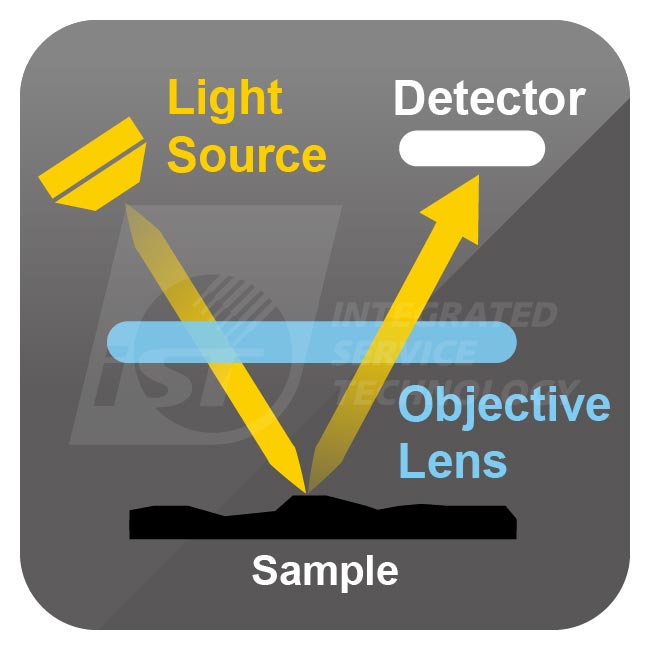

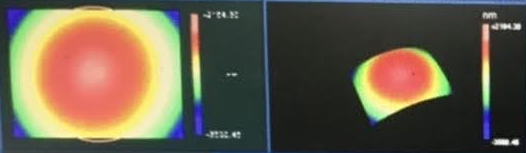

Densification! White Light Interferometry (WLI) Inspection Report

The White Light Interferometer (WLI) is a high-precision optical measurement system capable of detecting surface morphology at nanometer resolution.

When inspecting the mirror-polished surfaces of high-density ceramic components, WLI can accurately identify surface micro-defects such as pits, scratches, and voids.

SunRising’s Si₃N₄ / SiC samples were precision-polished and scanned using WLI. The results showed a continuous and smooth surface, with no detectable pores or microcracks.

With vertical resolution up to 1 nm and lateral resolution up to 300 nm, WLI reveals height variations when internal porosity connects to the surface.

However, no anomalies were observed during this test, indicating that the Si₃N₄ / SiC components exhibit very low porosity, dense microstructure, and excellent manufacturing quality.

This non-destructive WLI analysis allows us to quantify surface uniformity and integrity, providing a scientific foundation for quality control and process optimization. The results confirm that the sample meets high-density standards and is suitable for high-performance applications.

SGS High Thermal Conductivity SiC Inspection Report

Technical specifications of silicon nitride Si3N4 material.

| Item | Unit | Test Standard |

|---|---|---|

| Density | g/cm3 | 3.2 |

| Elastic Modulus | Gpa | 300 |

| Coefficient of Thermal Expansion | 10-6K-1 | 3.2 |

| Hardness (HV) | Mpa | 1600 |

| Fracture Toughness | Mpa | 7.0 |

| Flexural Strength (RT) | Mpa | 720 |

| Flexural Strength (700°C) | Mpa | 450 |

| Compressive Strength (RT) | Mpa | 2500 |

| Poisson’s Ratio | 0.25 | |

| Thermal Conductivity W | (mk)-1 | 20 |

| Volume Resistivity | ≥10¹⁵ | |

| Max Operating Temp (unloaded) | ℃ | 1100 |

| Acid and Alkali Resistance | Strong |