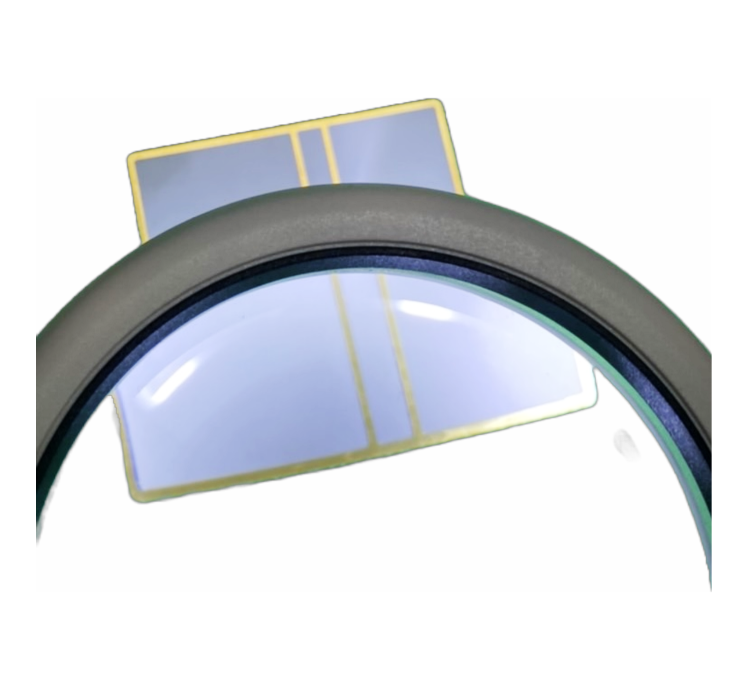

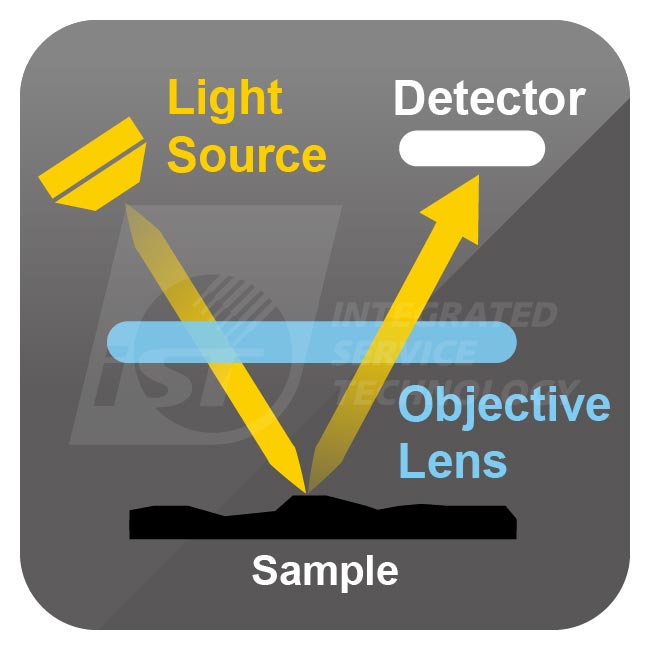

The White Light Interferometer (WLI) is a high-precision optical measurement technique capable of detecting the microscopic surface morphology of materials with nanometer-scale resolution。

When measuring the mirror-finished surfaces of high-density ceramic components, WLI can accurately capture surface micro-defects such as pits, scratches, and voids。

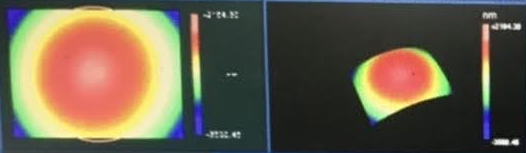

The SunRising Si₃N₄ / SiC composite was precisely polished to a mirror-finished surface and analyzed using White Light Interferometry (WLI). The scan results revealed a continuous and smooth surface, with no detectable pores or microcracks。

Thanks to WLI’s vertical resolution of up to 1 nm and lateral resolution of approximately 300 nm, any internal porosity connected to the surface would manifest as height variations in the interferometric image。

However, no such anomalies were observed during this test, indicating that the Si₃N₄ / SiC component possesses extremely low porosity, demonstrating a dense microstructure and high-quality fabrication。

Through WLI’s non-destructive inspection capabilities, we were able to quantify the surface uniformity and integrity of the ceramic material, providing a scientific basis for quality control and process optimization. The results confirm that this Si₃N₄ / SiC sample meets high-density standards, making it a reliable candidate for high-performance applications。

SGS Test Report!!