SunRising - White Light Interferometry (WLI) Inspection Report for SiC / Si₃N₄ Materials

The White Light Interferometer (WLI) is a high-precision optical measurement technology capable of detecting the microscopic surface morphology of materials with nanometer-scale resolution.

When inspecting the mirror-polished surfaces of high-density ceramic components, WLI can accurately capture surface micro-defects such as pits, scratches, or voids.

Pre-Polishing Surface Image – SunRising SiC / Si₃N₄

Surface Image After Polishing and Grinding

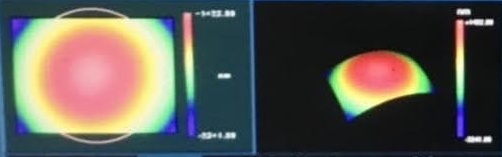

Figure 1. White Light Interferometry (WLI) Scan – SunRising SiC / Si₃N₄ Surface

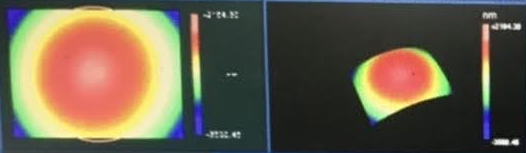

Figure 2. White Light Interferometry (WLI) Scan – SunRising SiC / Si₃N₄ Surface

The Si₃N₄ / SiC material from SunRising was precision-polished to a mirror-like finish and analyzed using a White Light Interferometer (WLI). The results showed that the surface was continuous and smooth, with no detectable pores or microcracks.

Given that the WLI offers a vertical resolution of up to 1 nm and a lateral resolution of up to 300 nm, any internal porosity connected to the surface would appear as height variations in the interferometric scan.

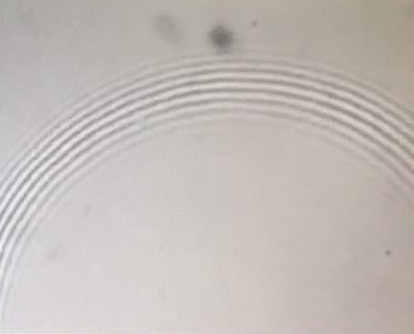

White Light Interferometry (WLI) Scan of SunRising SiC / Si₃N₄ Surface

However, no abnormalities were observed during this test, indicating that the Si₃N₄ / SiC component has a very low porosity, a dense microstructure, and excellent manufacturing quality.

Through the non-destructive inspection capabilities of the White Light Interferometer (WLI), we are able to quantitatively evaluate the uniformity and integrity of the ceramic surface, providing a scientific basis for quality control and process optimization. The results confirm that this Si₃N₄ / SiC sample meets high-density standards and is well-suited as a key material for high-performance applications.

Figure. White Light Interferometry (WLI) Scan – SunRising SiC / Si₃N₄ Surface