High-Purity Thermal Management Silicon Carbide (HT-SiC) Material

- Application Areas:

- 1. High-voltage power module heat dissipation substrates

- 2. 5G base station laser thermal management modules

- 3. EV SiC MOSFET cooling substrates

- 4. Radar power module thermal substrates

- 5. Server and AI chip heat dissipation

- 6. GPU and CPU cooling substrates

- 7. Liquid cooling / Immersion cooling cold plates

- 8. EV & power electronics SiC IGBT and SiC MOSFET inverter cooling for electric drive systems

High-Thermal-Conductivity Silicon Carbide (SiC)

High thermal conductivity silicon carbide (SiC) (>170W/m·K) is a wide-bandgap ceramic material characterized by its high breakdown voltage, strong electric field resistance, and high current density capacity.

In addition to its excellent thermal conductivity, it also surpasses conventional ceramic materials in terms of hardness, heat resistance, oxidation resistance, corrosion resistance, and overall durability.

These properties make SiC increasingly favored in recent years for applications such as structural components in mechanical engineering, seals in chemical processing, and operations in extreme environments involving strong acids, strong alkalis, high wear, high temperatures, and even aerospace conditions.

1. **High Thermal Conductivity** – SiC offers excellent heat dissipation properties. Compared to aluminum and copper, it features a lower coefficient of thermal expansion, making it ideal for integration with semiconductors or ceramic substrates to reduce thermal mismatch-induced stress.

2. **Thermal Stability** – SiC remains stable under extreme temperature conditions, making it suitable for the long-term cooling demands of high-power electronic components.

3. **Durability** – SiC heat dissipation modules are more durable than metal heat sinks, performing reliably in high-temperature and high-stress environments.

4. **Future-Ready Technology** – High thermal conductivity SiC modules are expected to play a key role in next-generation systems such as AI servers, 5G base stations, EV fast-charging systems, and aerospace electronics.

Main Features:

● High Thermal Conductivity (>170W/m·K)

● High Electrical Resistivity

● Excellent Dielectric Strength

● Low Coefficient of Thermal Expansion

● High Temperature Resistance and Reliability

● Strong Mechanical Strength and Impact Resistance

● Acid and Alkali Resistance, Corrosion Resistance

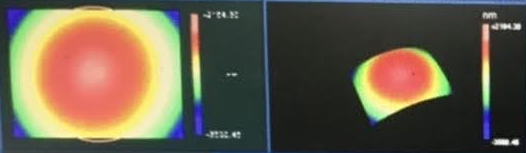

Densification Analysis – White Light Interferometry (WLI) Inspection Report

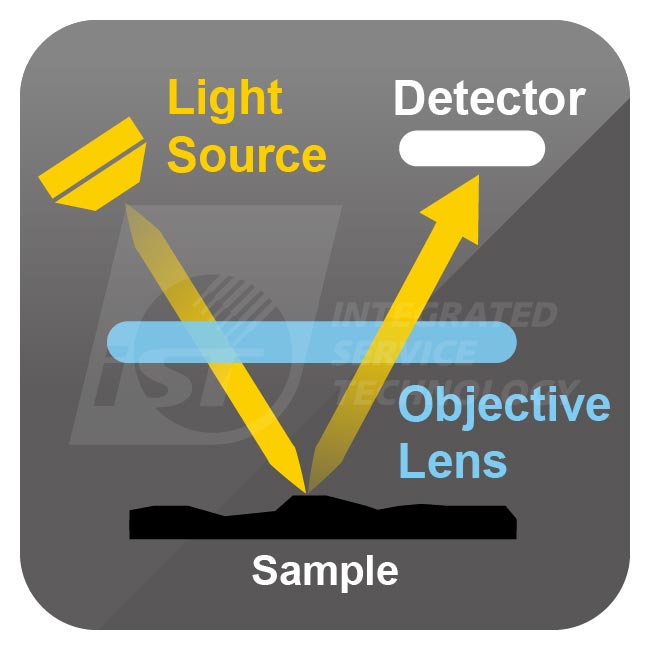

The White Light Interferometer (WLI) is a high-precision optical measurement technology capable of detecting the microscopic surface morphology of materials with nanometer-level resolution。

When measuring the mirror-polished surfaces of high-density ceramic components, WLI can accurately detect surface micro-defects such as pits, scratches, and voids。

The SunRising Si₃N₄ / SiC composite was precisely polished to a mirror-finished surface and analyzed using White Light Interferometry (WLI). The scan results revealed a continuous and smooth surface, with no detectable pores or microcracks。

Thanks to WLI’s vertical resolution of up to 1 nm and lateral resolution of approximately 300 nm, any internal porosity connected to the surface would manifest as height variations in the interferometric image。

However, no such anomalies were observed during this test, indicating that the Si₃N₄ / SiC component possesses extremely low porosity, demonstrating a dense microstructure and high-quality fabrication。

Through WLI’s non-destructive inspection capabilities, we were able to quantify the surface uniformity and integrity of the ceramic material, providing a scientific basis for quality control and process optimization. The results confirm that this Si₃N₄ / SiC sample meets high-density standards, making it a reliable candidate for high-performance applications。

SGS 官方檢測報告!! SGS Test Report!!

Technical Specifications of High-Thermal-Conductivity Silicon Carbide (SiC) Materials

| Spec | Unit | Test Standard |

|---|---|---|

| Purity | % | ≧ 98.5 |

| Density | kg/cm3 | 3.16 |

| Mohs Hardness | CNS3299:2006 | 9 |

| Flexural Strength | Mpa(ASTM D790-17) | 337 |

| Thermal Conductivity | W(m*k) | ≧ 170 |

| Electrical Resistivity(Ω) | 500 V/sec ( JIS K6911:1995 ) | ≧ 4.34 x 107 |

| oefficient of Thermal Expansion (CTE) | 23~200 °C (ASTM E831-19) | 3.266 x 10-6 |

| oefficient of Thermal Expansion (CTE) | 23~500 °C (ASTM E831-19) | 3.913 x 10-6 |

SunRising - White Light Interferometry (WLI) Inspection Report for SiC / Si₃N₄ Materials

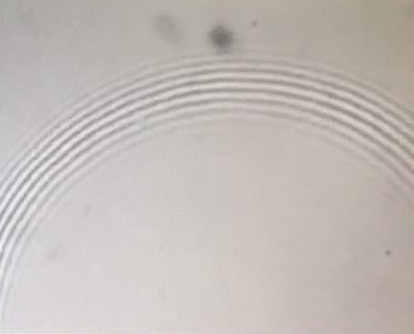

The White Light Interferometer (WLI) is a high-precision optical measurement technology capable of detecting the microscopic surface morphology of materials with nanometer-scale resolution.

When inspecting the mirror-polished surfaces of high-density ceramic components, WLI can accurately capture surface micro-defects such as pits, scratches, or voids.

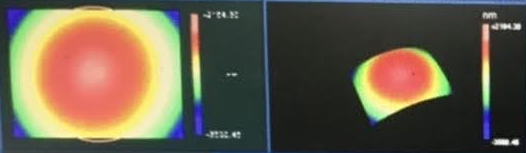

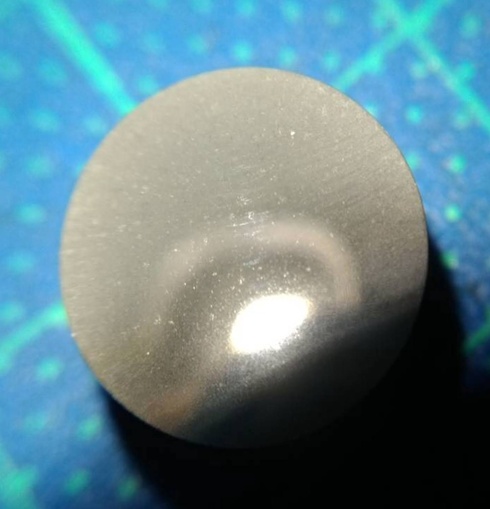

Pre-Polishing Surface Image – SunRising SiC / Si₃N₄

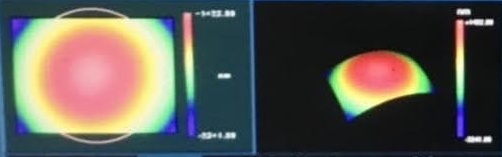

Surface Image After Polishing and Grinding

Figure 1. White Light Interferometry (WLI) Scan – SunRising SiC / Si₃N₄ Surface

Figure 2. White Light Interferometry (WLI) Scan – SunRising SiC / Si₃N₄ Surface

The Si₃N₄ / SiC material from SunRising was precision-polished to a mirror-like finish and analyzed using a White Light Interferometer (WLI). The results showed that the surface was continuous and smooth, with no detectable pores or microcracks.

Given that the WLI offers a vertical resolution of up to 1 nm and a lateral resolution of up to 300 nm, any internal porosity connected to the surface would appear as height variations in the interferometric scan.

White Light Interferometry (WLI) Scan of SunRising SiC / Si₃N₄ Surface

However, no abnormalities were observed during this test, indicating that the Si₃N₄ / SiC component has a very low porosity, a dense microstructure, and excellent manufacturing quality.

Through the non-destructive inspection capabilities of the White Light Interferometer (WLI), we are able to quantitatively evaluate the uniformity and integrity of the ceramic surface, providing a scientific basis for quality control and process optimization. The results confirm that this Si₃N₄ / SiC sample meets high-density standards and is well-suited as a key material for high-performance applications.